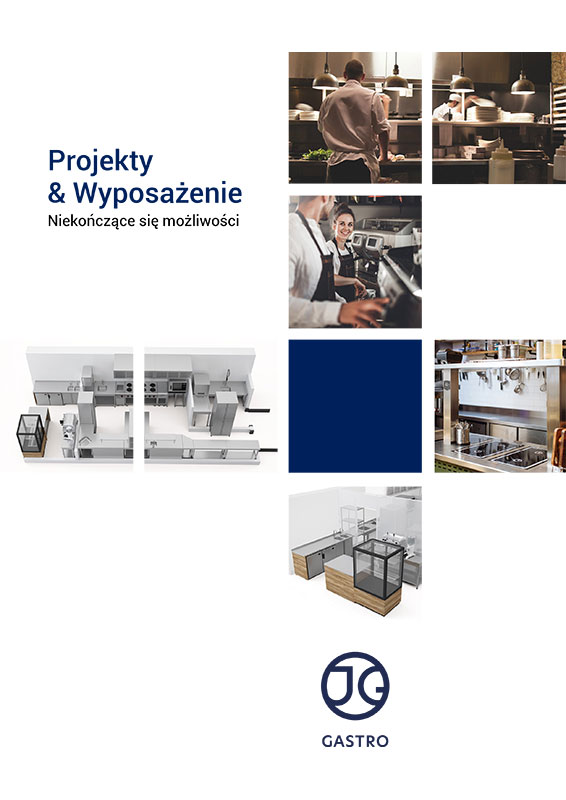

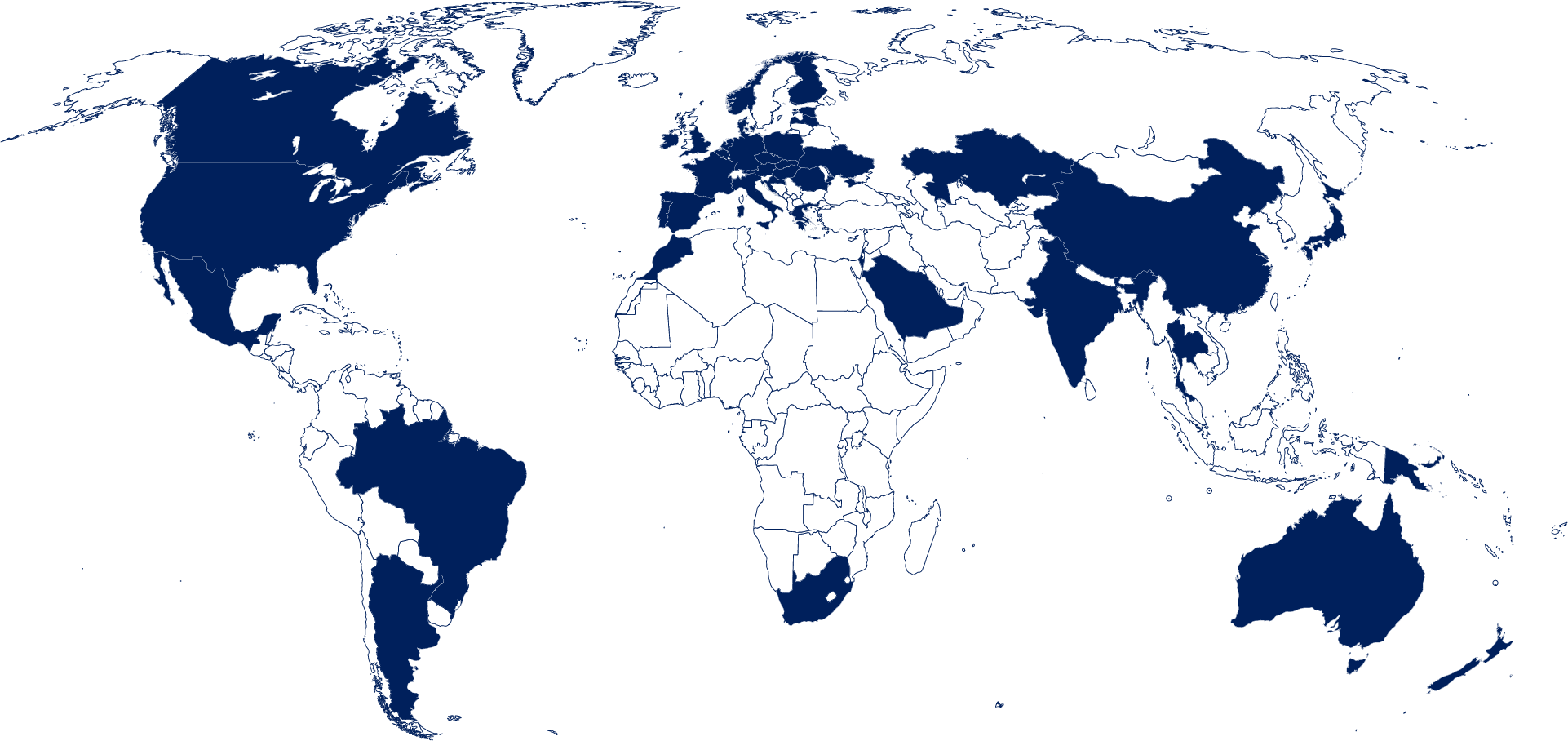

We have been involved in catering equipment since 2007. Completed projects and gained experience result in projects that can be seen in our references. Most of our investments are made on repeatable equipment and proven solutions, which allows us to eliminate errors and deliver equipment that we have already tested.

We do not aim to be an expensive company. We also do not supply the cheapest equipment on the market. Our goal is to prepare a good, optimized work environment and select relatively trouble-free machines.

Designing and opening a gastronomic venue is a complex and multi-level process. It is necessary to combine vision, capabilities, technical conditions, and ultimately bring everything to fruition. Navigating through the intricacies of each stage, coordinating designers and contractors can be time-consuming and costly.

To meet the needs of investors who value their time and would like the entire process of opening a venue to run smoothly, we offer the possibility of taking over some responsibilities such as designing the backroom and interior, preparing installation guidelines, adapting the venue and its equipment.

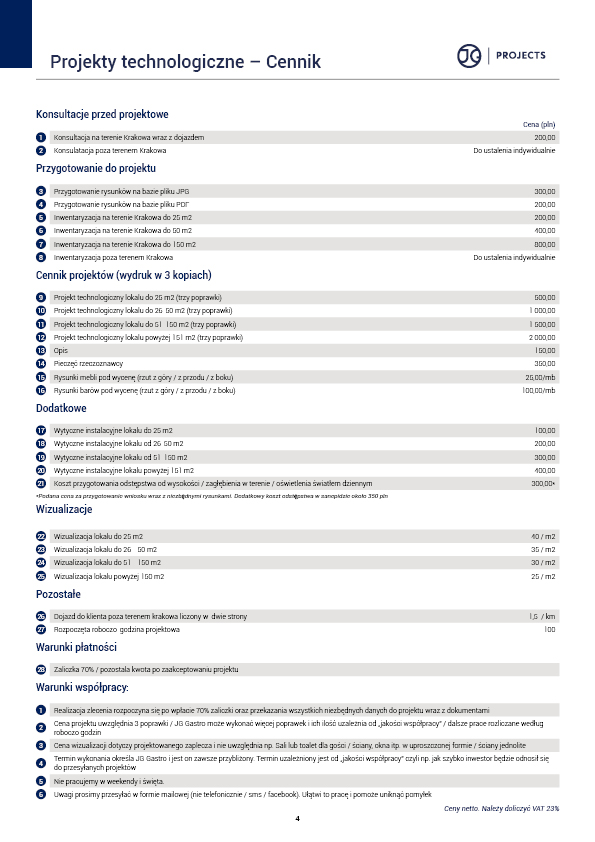

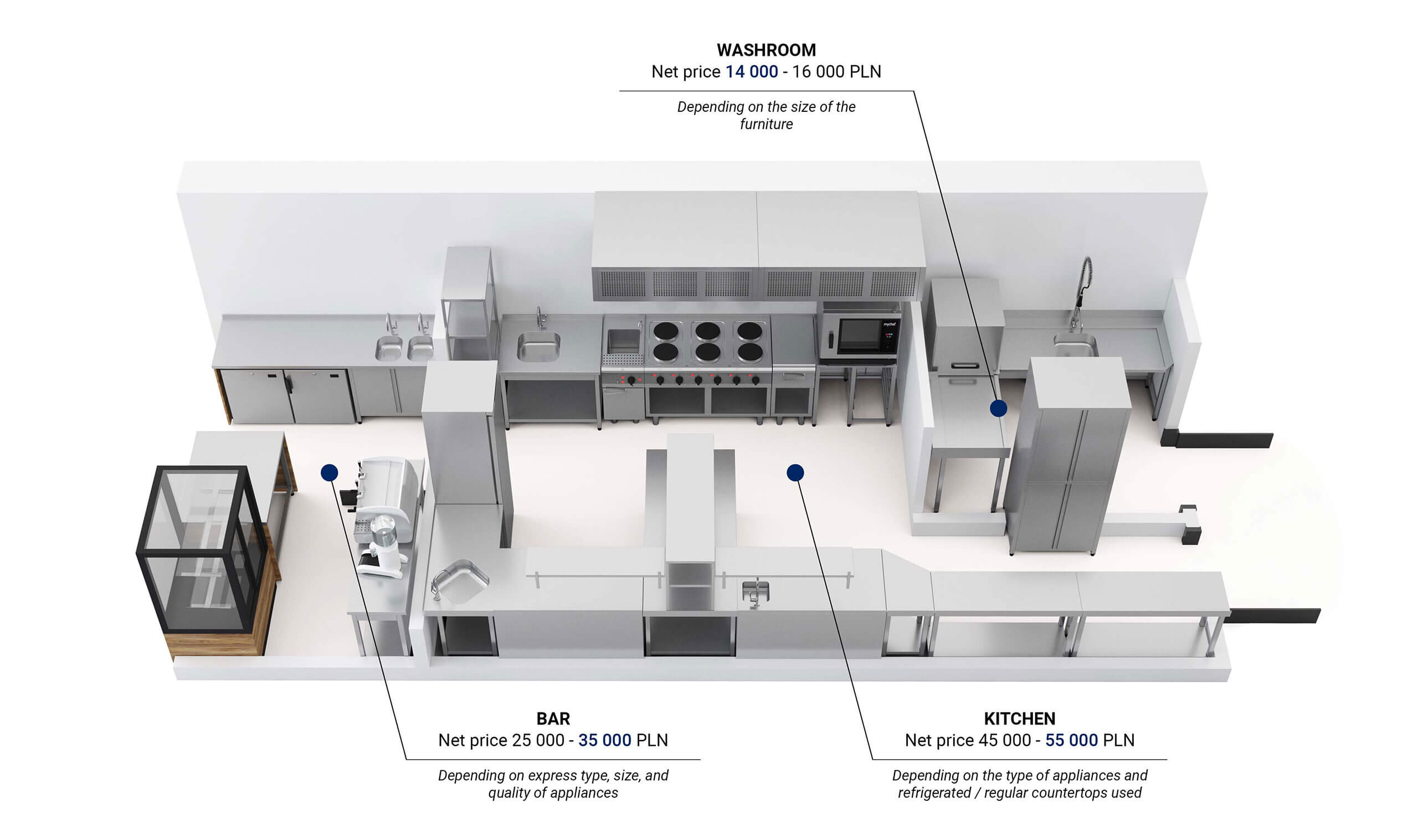

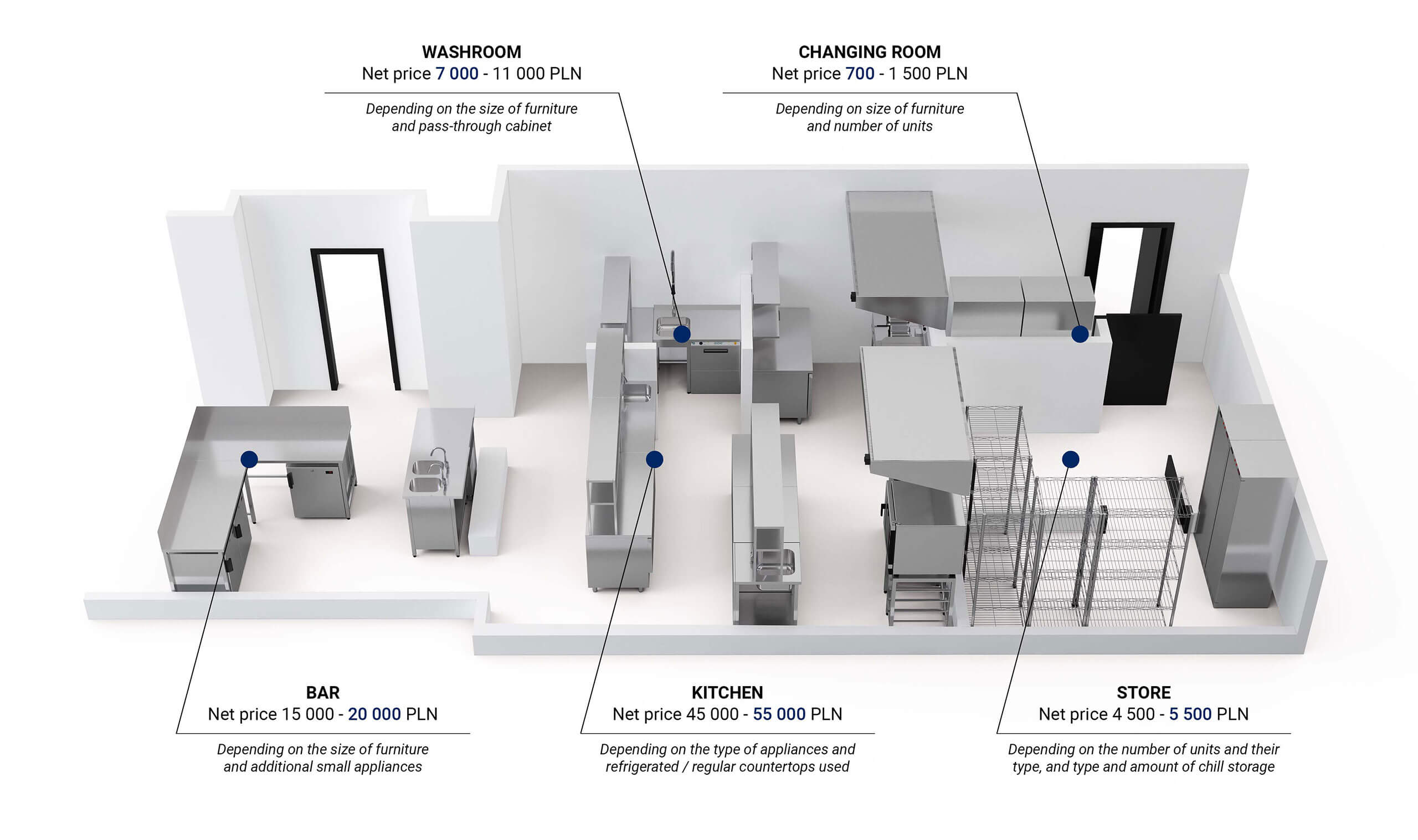

Managing the entire or part of the investment with one company allows for better control, eliminates the need to coordinate contractors, and saves time. Additionally, we have prepared clear and transparent project price lists divided into segments and sample estimates of premises equipment and additional equipment – never before has the whole process been so clear.

We invite you to contact us for a discussion.

We carry out technological projects in-house, which allows us to have control over the course of the investment and makes it easier for us to supervise it.

Ultimately, we strive to be a partner. Only in an atmosphere of respect and mutual understanding can great projects be created.